1. Key Technologies and Core Applications by Stage

1. Early Stage (19th Century to Early 20th Century)

Technological Achievements:

- Chemical Method: Nitrogen is obtained by decomposing nitrates or separating gases after combustion, with early exploration of liquid air distillation techniques.

- Breakthroughs: Achieved laboratory-level nitrogen separation, with purity below 90%.

Applications:

- Small-scale chemical raw material preparation in laboratories (e.g., nitrate synthesis).

Limitations:

- Low Efficiency: Relied on complex chemical reactions; equipment was bulky and not industrialized.

- Insufficient Purity: Could not meet high-purity demands, limiting application range.

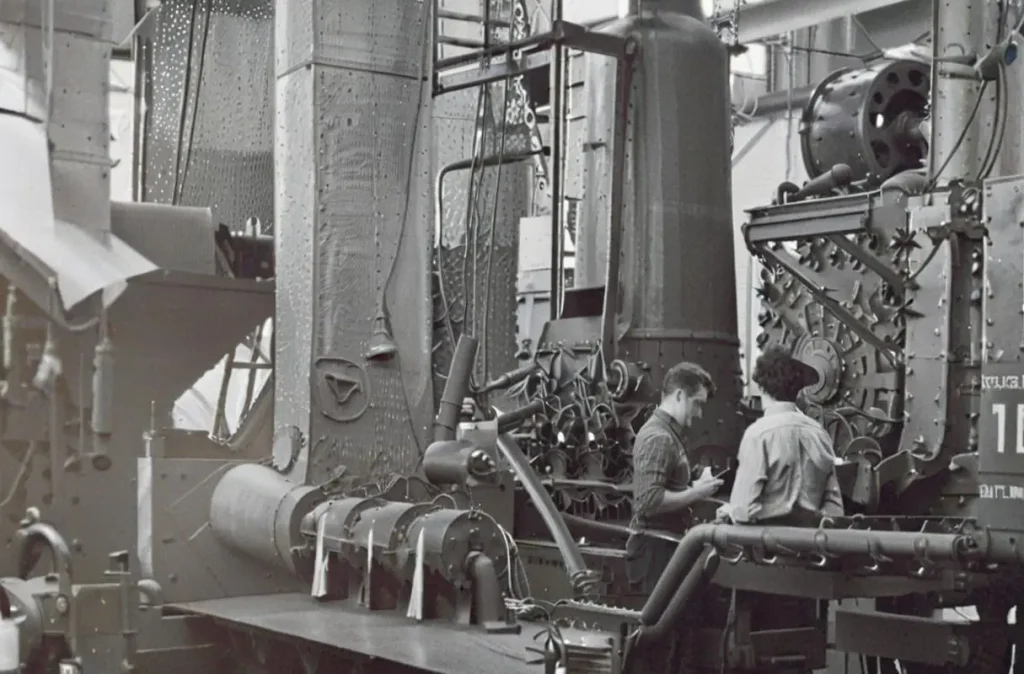

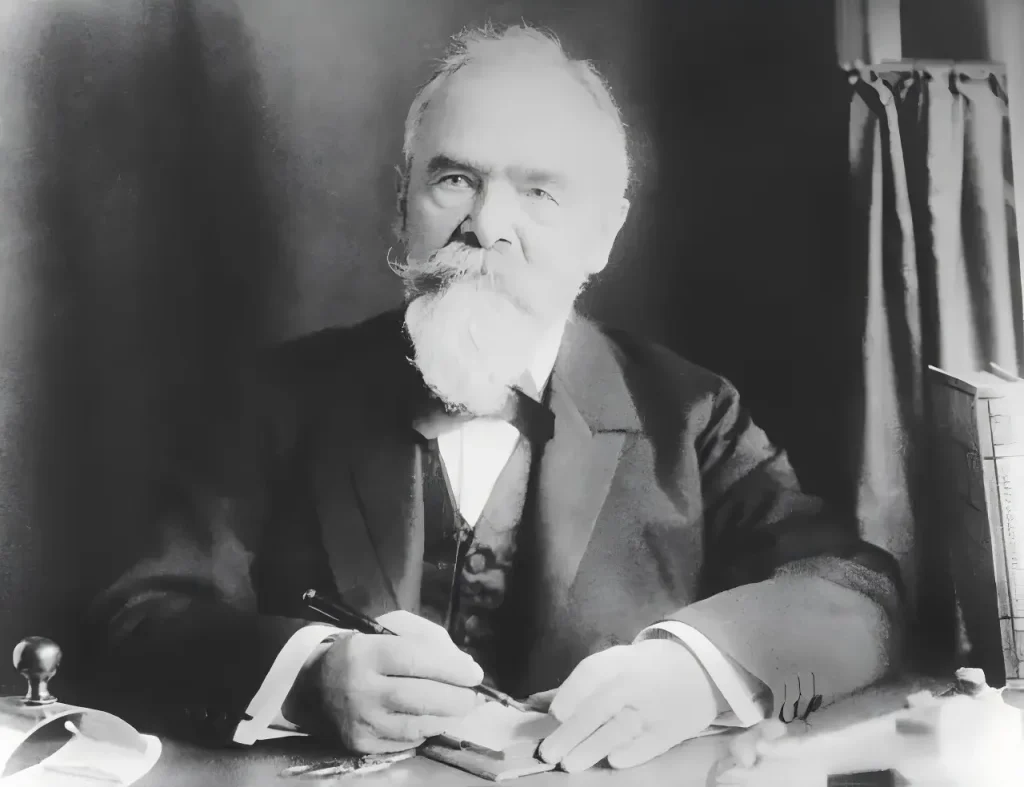

2. Cryogenic Air Separation (Early to Mid 20th Century)

Technological Achievements:

- Air Liquefaction Technology: Carl von Linde invented an air liquefaction device using boiling point differences to distill liquid air.

- Industrial Breakthrough: Nitrogen purity reached 99.999%, enabling large-scale production.

Applications:

- Steelmaking (blast furnace protection gas), chemical synthesis (ammonia production), medical cryogenics.

- Aerospace liquid nitrogen fuel storage.

Limitations:

- High Energy Consumption: Requires cooling air to -196°C, leading to high energy costs.

- Long Startup Time: Pre-cooling takes several hours, with poor flexibility.

- Complex Equipment: Requires large infrastructure and high maintenance costs.

3. Pressure Swing Adsorption (PSA, 1960s–1970s)

Technological Achievements:

- Carbon Molecular Sieve Technology: Erich Eder of Germany commercialized the process, allowing oxygen to be selectively adsorbed, enriching nitrogen.

- Modular Design: Compact equipment with customizable nitrogen purity (95%–99.999%).

Applications:

- Food packaging: Nitrogen preservation (e.g., chip nitrogen flushing).

- Electronics manufacturing: Semiconductor oxidation prevention.

- Pharmaceutical industry: Inert gas protection in drug synthesis.

Limitations:

- High Initial Cost: High-end PSA equipment had a high investment threshold.

- Air Source Quality Dependency: Requires strict filtering of impurities (oil mist, particles).

- Complex Maintenance: Adsorbents need regular replacement, increasing operational costs.

4. Membrane Separation Technology (1980s)

Technological Achievements:

- Hollow Fiber Membrane: Generon, USA, introduced commercial products, using the difference in oxygen permeability rates to separate nitrogen.

- Low Energy Consumption Design: Operating pressure only requires 0.5–1.0MPa, reducing energy consumption by 50% compared to cryogenic methods.

Applications:

- Mobile applications: Oil drilling platforms, vehicle-mounted nitrogen production.

- Food processing: Beer bottling inert protection.

- Laboratories: Low-purity nitrogen needs (e.g., routine lab environments).

Limitations:

- Purity Limits: Maximum purity reaches only 99.5%, insufficient for high-demand fields like semiconductors.

- Temperature Sensitivity: High temperatures or humidity reduce separation efficiency.

- Membrane Component Lifespan: Pollution or mechanical damage requires frequent replacement, adding costs.

5. Modern Development Stage (21st Century to Present)

Technological Achievements:

- Hybrid Technology: Combining PSA with membrane separation to balance purity and energy consumption (e.g., VPSA technology reduces energy consumption by 30%).

- New Material Breakthroughs: Nanocomposite materials and carbon molecular sieve optimizations improve adsorption efficiency.

- Intelligent Control: IoT real-time monitoring and PLC systems automatically adjust parameters.

Applications:

- New energy: Lithium battery production (electrolyte drying).

- Semiconductor: Chip manufacturing (ultra-high-purity nitrogen 99.9999%).

- Medical: Liquid nitrogen cryotherapy (tumor ablation).

Limitations:

- Technical Complexity: Requires interdisciplinary integration (material science, AI algorithms), with high R&D costs.

- Market Competition: High-end equipment depends on imported core components (e.g., high-performance membrane materials).

- Environmental Pressure: Balancing energy efficiency and carbon emissions, some technologies sacrifice performance.

2. Modern Application Pain Points and Leasing Model Value

Traditional nitrogen generator purchase involves high capital investment, equipment idle risks, and high maintenance costs, particularly burdensome for SMEs and temporary projects. Fooen’s nitrogen generator leasing solutions address these challenges by offering:

- Flexible Supply: Containerized nitrogen generators with modular designs support rapid deployment and scalable expansion.

- Technical Support: Professional engineering team on-site to ensure stable operation and safety.

- Cost Optimization: Leasing reduces fixed asset investment, avoids equipment idle losses, and provides access to the latest technology upgrades.

- Scenario Adaptability: Covers full-cycle needs from temporary projects to long-term production, customizable nitrogen purity and flow, meeting various industry standards.

Transition from “Ownership” to “Resource Efficiency”

Fooen’s leasing model transforms nitrogen generators from “fixed assets” into “on-demand resources,” alleviating financial and operational pressures for enterprises, while driving the industry towards greener and smarter upgrades. As the trend toward industrial services deepens, leasing models may become the mainstream choice for businesses and major projects.