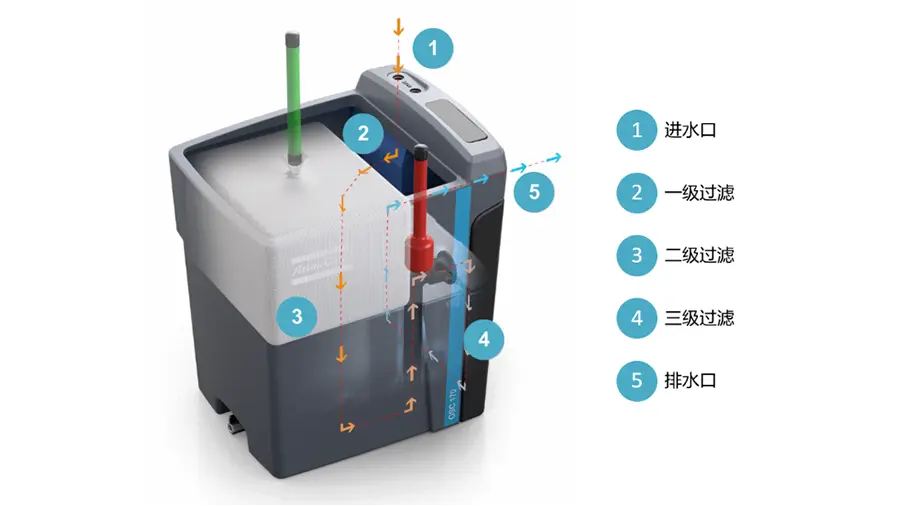

In August 2021, the Compressor Division of Atlas Copco officially launched the next-generation OSC oil-water separator. Designed as a highly efficient and user-friendly condensate treatment system, the newly designed OSC separator features a more compact footprint. Its three-stage filtration system ensures that the residual oil content in the treated condensate remains below 10 ppm, meeting China’s GB8978-1996 Integrated Wastewater Discharge Standard Level II. This allows direct discharge into drainage systems, eliminating environmental risks associated with untreated condensate.

During the operation of oil-injected screw air compressors, the lubricating oil used in the compressor inevitably mixes with compressed air and condensate. While oil contamination in the compressed air is often addressed using pipeline filters, the oil in the condensate is frequently overlooked. Direct discharge of untreated condensate into drainage systems poses significant environmental threats.

To thoroughly remove oil from condensate and address different types of lubricants used in oil-injected compressors, Atlas Copco’s new OSC series offers both activated carbon and organoclay models. Each unit comes equipped with service indicators for filter replacement, blockage alerts, and a sampling port, making operation simple and intuitive. The activated carbon and organoclay filter cartridges are easy to install and replace. Additionally, the maintenance interval for the new OSC series has been extended to 4,000 hours.

Atlas Copco is committed to a greener future—its next-generation OSC oil-water separator is designed to work hand-in-hand with customers in protecting our blue skies and green waters.

(Content originally from Atlas Copco. If there is any infringement, please contact us for removal.)