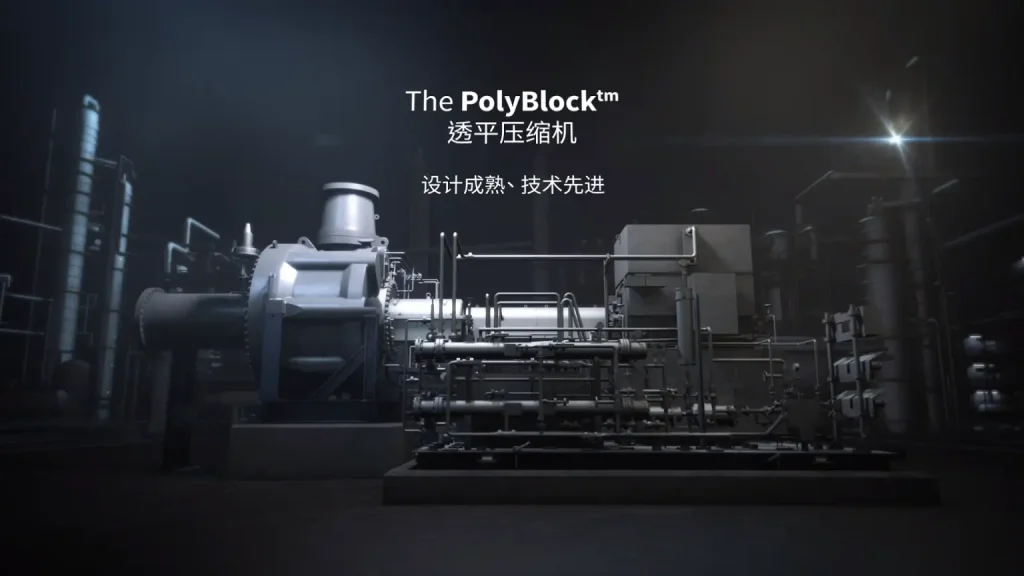

Polyolefins are essential raw materials in plastic production, manufactured through complex chemical and petrochemical processes. Drawing on its extensive expertise in both integrally geared and gearless centrifugal compressor technologies, Atlas Copco Gas and Process Division has developed the PolyBlock™ compressor—a purpose-built solution for polypropylene (PP) applications. The PolyBlock™ is engineered to safely and reliably handle the demanding challenges of PP processes, fulfilling the requirements of both process licensors and end users.

Application of the Atlas Copco PolyBlock™ Circulating Gas Compressor in Polypropylene Production

The production process for polypropylene is intricate, and the reactor unit is a critical step where the PolyBlock™ compressor plays a vital role. After exiting the compressor, the circulating gas enters the reactor. As it flows, it fluidizes the polypropylene particles, which then react with the catalyst to undergo polymerization. The upward flow of gas also removes the reaction heat while its temperature increases, thus preparing the mixture for the next processing stage.

Key Features of the Atlas Copco PolyBlock™ PP Compressor

✅ Proven Reliability in Demanding Conditions

Co-developed with LyondellBasell (formerly Basell), this compressor is specifically designed to meet the rigorous demands of the olefins industry, particularly for circulating gas compression in PP plants. The PolyBlock™ is optimized to handle gas media containing particulates and powder, offering stable operation, broad control range, and excellent process adaptability.

✅ Faster Delivery, Greater Convenience

A modular and standardized component design reduces delivery time, accelerates commissioning, and lowers capital investment costs.

✅ Easy Maintenance for Continuous Operation

The direct-drive compressor features a plug-in rotor core that can be easily withdrawn from the rear, giving technicians full access to rotating components such as dry gas seals, impellers, bearings, and vibration probes. This enhances serviceability and minimizes downtime.

✅ 40 Years of Expertise in PP/PE, Global References

With over four decades of experience in polyolefin applications, Atlas Copco has become a trusted supplier with over 100 reference customers worldwide. The PolyBlock™ is endorsed by several international process licensors, making it a benchmark compressor in the PP and PE sectors.